Well Jim asked earlier about how to make some flow forge treads, and funny enough i was making some at work over the past few days, so here goes...Firstly i made a jig the width of the steps, I used a bit of offcut channel and a few clamps Then i made some end plates out of 80mm x 6mm and punched 2 x 14mm holes for the M12 bolts

Then i made some end plates out of 80mm x 6mm and punched 2 x 14mm holes for the M12 bolts The flow forge grating i cut to width using a grinder and a cutting disk, To cut the length i took the full length of grating and cut it on the bandsaw. Its quicker easier and cuts it nice and square

The flow forge grating i cut to width using a grinder and a cutting disk, To cut the length i took the full length of grating and cut it on the bandsaw. Its quicker easier and cuts it nice and square next we need to put the end plates on the jig, i used bolts to hold them flat and upright,

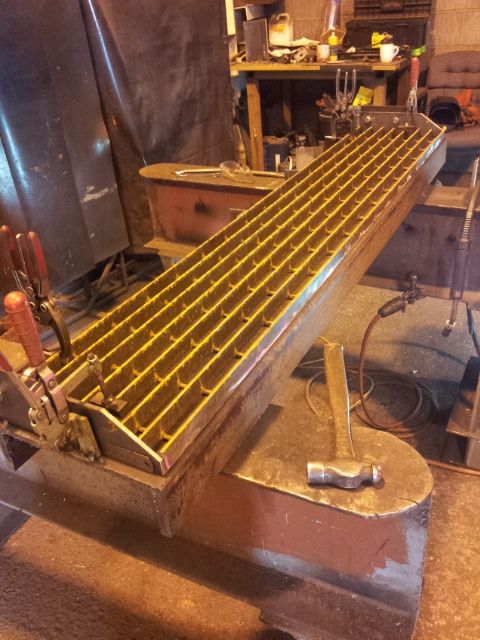

next we need to put the end plates on the jig, i used bolts to hold them flat and upright,  Then stick the grating in there, make sure that you have the top face on the bottom, its easy to get confused

Then stick the grating in there, make sure that you have the top face on the bottom, its easy to get confused

Now we need to tack the tops of the flats all way along both sides

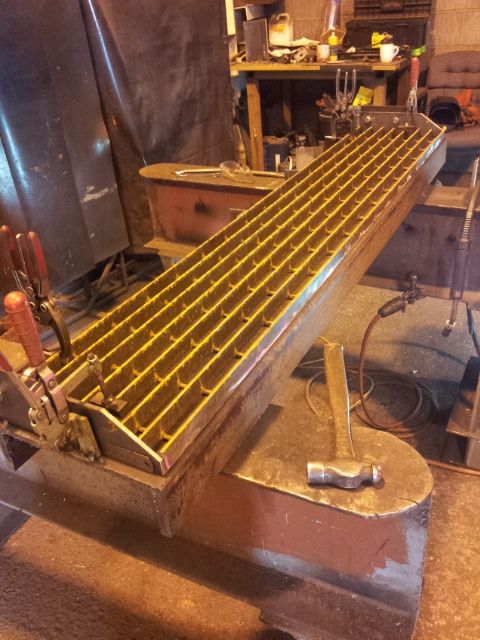

Now we need to tack the tops of the flats all way along both sides When its done both sides we take it out from the jig and get ready to weld the flats

When its done both sides we take it out from the jig and get ready to weld the flats And this is what it looks like welded up, Some people weld both sides but i just weld one side, Thats plenty strong enough.

And this is what it looks like welded up, Some people weld both sides but i just weld one side, Thats plenty strong enough. Tack the tops of the flats

Tack the tops of the flats and then sand flush

and then sand flush And there you have it, so easy and far cheaper than buying ready made

And there you have it, so easy and far cheaper than buying ready made You can make an imporovement by add a 3mm durbar strip along the frond end, to act like a non slip tread

You can make an imporovement by add a 3mm durbar strip along the frond end, to act like a non slip tread

As the title says i need some serious voting if i'm ever going to weld up that space station in the sky, Alternatively if you guys want a bit of piece and quiet and want to get me off the planet in order to get some , well thats fine by me also  I need to get as many Votes as i can, so please can you vote for me?https://www.lynxapollo.com/en_GB/110101/gerry-sharpe

I need to get as many Votes as i can, so please can you vote for me?https://www.lynxapollo.com/en_GB/110101/gerry-sharpe

Over the past few days we've been getting loads of new Welding and Fabrication work in the welderfab job boards, some days we see an excess of over 500 new welding jobs entered in the moderation queue, each one of those jobs needs to be checked before being approved for inclusion to the job boards.We're looking for a Global moderator who can help keep the job boards clean and tidy, its pretty easy to do, its just a bit much for one person to do every day (me!!)If your a welder/Fabricator with a passion for Welding and Engineering in General, and would like to be part of the UK newest and Biggest Welding Jobsite, Then send me a PM or email me direct admin@welderfab.co.ukWe don't expect much, just help out when you can, We have a zero approach to Spam on this site, so much so that systems are in place to stop spam 100%, your responsibilities would involve:-1. Being an active member of the forums2. Moderating the Job boards and approving/deleting jobs when necessary (Training given)3. Helping , greeting and welcoming new members4. Generally having fun, and making this "The" Place for Welders and fabricators in the UK ThanksGerry